Copper Gas Line Fitting & Safety Guide

Did you know roughly 90% of tool outlets offer to cut and cut threads in black iron pipe for an extra fee? This piece of data reveals the strong demand and readily available to gas piping materials, especially copper gas lines. Many homes now favor copper for its strength, dependability, and corrosion resistance. This guide will discuss the essentials of copper gas lines, their merits, and critical safety measures for fitting. With insights from Installation Parts Supply, you’ll learn important aspects of gas line installation. This knowledge guarantees both safety and adherence to codes while fulfilling your gas piping specifications.

Notable Observations

- Copper gas lines provide robustness and resistance to corrosion.

- Fitting demands accurate dimensions and following local code regulations.

- Protective steps are essential to secure leak-free gas lines.

- Comprehending the proper routing and placement is vital for effective installation.

- Routine upkeep increases the durability of copper gas lines.

Comprehending the Fundamentals of Copper Gas Lines

Copper gas lines are widely used in both residential and commercial environments. They’re appreciated for safety and dependability. Studying type l copper wall thickness, including their advantages and how they stack up against other materials, is vital. This understanding empowers homeowners to make well-informed choices.

What is a Copper Gas Line?

A copper gas line uses copper piping for natural gas and propane distribution. It complies with established regulations like the National Fuel Gas Code (NFPA 54/ANSI Z223.1). In areas such as Minnesota and Florida, it’s the top choice for home fuel gas piping. Since 1999, agencies such as IAPMO have endorsed its use in fuel gas systems.

Merits of Utilizing Copper Gas Lines

Copper gas lines provide several notable advantages. They include:

- Corrosion Resistance: Copper excels over steel and black iron in withstanding rust.

- Flexibility: Its pliability facilitates setup, even in intricate configurations.

- Durability: Copper gas lines offer long life and robust construction, minimizing the need for replacements.

- Safety: Complying with strict standards, copper tubing is considered secure for gas distribution.

Comparison with Other Materials

In comparing copper and steel for gas lines, copper often prevails. Black iron pipes are still common, especially in metropolises such as Chicago. Even so, copper’s lighter weight and ease of handling have increased its usage. Although roughly 50% of gas companies have switched to stainless steel owing to regulations, copper’s advantages hold strong in certain situations. This is especially true in areas like St. Louis, where modern residences frequently feature copper gas lines.

| Supplies Needed | Tools for Copper Gas Line Installation |

|---|---|

| Copper tubing (Type K and Type L) | Wrench tools |

| Connectors and fittings | Copper pipe cutter |

| Teflon tape | Soldering kit |

| Safety apparatus (gloves, goggles) | Pressure meter |

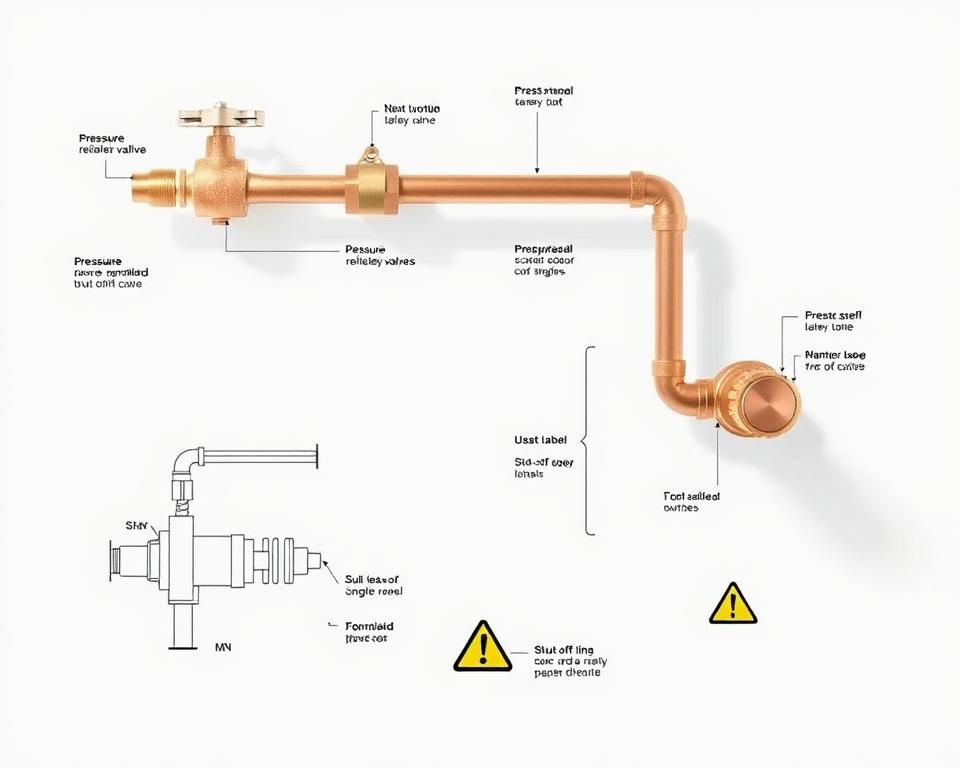

Optimal Methods for Copper Gas Line Installation

Installing copper gas lines entails specific best practices to uphold protection and productivity. Primary elements of the process comprise accurate planning of routes, secure connections, and comprehensive leak testing. These steps ensure a gas piping system that is both safe and compliant.

Placement and Routing for Copper Gas Lines

Thoughtful planning is crucial when routing copper gas lines. It is necessary to keep these lines distant from structural features that could inflict harm. This strategy averts electrochemical corrosion by avoiding contact with different metals. Also, ensuring easy access for future upkeep and fixes is a must by maintaining clearances.

Adhering to these routing and positioning guidelines boosts the system’s safety and durability.

Joining and Sealing Pipes Properly

Making firm attachments in copper gas pipes necessitates specific materials. Use gas-grade plumber’s tape and gas-specific sealants only. Refrain from regular thread seal tape to prevent leaks from lubricants on threads. By following proper connection and sealing strategies, the chance of gas leaks is markedly diminished, in accordance with safety and regulatory requirements.

Testing for Leaks Post-Installation

Post-installation, conducting a thorough leak test is critical. Start with a pressure test, applying 1.5 times the system’s maximum working pressure for no less than 10 minutes. Alternatively use a soapy water solution to reveal leaks through the formation of bubbles. The desired pressure for these tests should be approximately 9 inches w.c., with a minor deviation permitted. These methods of leak detection are essential for guaranteeing the safety of the gas system, which secures both assets and lives.

Copper Gas Line Safety Standards

Understanding and adhering to the various standards and codes is crucial for copper gas line safety. These rules ensure compliance and reduce risks such as leaks and failures. Both residents and professionals need to closely follow local building codes. They are required to secure the required permits before initiating any projects.

Grasping Local Building Code Standards

Local building codes dictate the standards for fitting copper gas lines. They address issues like installation depth, required support systems, and methods for preventing corrosion. For underground pipes, there is usually a requirement for 18 inches of burial. However, in some cases, this can be reduced to 12 inches. Metal sleeves are also often required for copper tubing that passes through wall plates near open edges.

Review and Adherence

Regular examinations by certified professionals are vital for gas line safety. They verify that installations adhere to both the National Fuel Gas Code and local building codes. These evaluations assess whether copper pipes are appropriately fastened and if holes drilled through joists are the proper dimensions. Adhering to these criteria improves safety and guarantees dependable function of gas line installations over time.

Tackling Frequently Encountered Issues in Copper Gas Lines

Copper gas lines, renowned for their longevity, can experience corrosion problems. It’s crucial to comprehend possible issues and necessary upkeep to guarantee safety. Identifying signs of corrosion and the benefits of regular maintenance can prevent gas leaks. This information combined with a comparison between copper and steel gas lines assists in selecting the optimal material.

Copper Gas Line Corrosion Issues

Over time, copper gas lines may corrode due to environmental factors or installation faults. Telltale signs include color changes, flaking, and unexpected gas bill hikes. Such damage can result in gas leakage, as evidenced by a rotten egg smell from supplementary mercaptan. After building or digging, inspecting for noticeable damage is crucial.

Maintaining Your Copper Gas Line

For security and performance, maintaining copper gas lines is essential. Annual inspections can identify initial signs of corrosion and problems. Ensuring appliances remain clean and properly ventilated prevents gas buildup and carbon monoxide dangers. Only licensed technicians should manage repairs and installations, ensuring safety code compliance and reducing failure risks.

Copper Gas Line vs. Steel: Pros and Cons

Deciding between copper and steel gas lines involves weighing pros and cons. Copper’s malleability simplifies setup in tight spaces and typically offers better corrosion resistance. In contrast, steel lines may offer greater longevity and cost less for some projects. Considering these aspects aids in choosing the right material for your needs.

The Bottom Line

The necessity of following optimal methods for copper gas line installation is paramount. Adherence to safety standards and local codes ensures effective performance and security. The manual also highlights copper gas lines’ benefits, such as robustness and rust resistance. However, it’s crucial to remain informed about material-related developments.

Maintenance is key to the longevity and function of copper gas lines. Correct setup and routine evaluations reduce the likelihood of corrosion and system failures. Being informed about local code changes is imperative to avoid fines or costly repairs for non-compliance.

Choose expert advice for copper gas line projects as it is greatly beneficial. Installation Parts Supply provides comprehensive expertise and assistance. They guarantee your project aligns with all safety requirements, improving your system’s safety and reliability.

Frequently Asked Questions

What is a copper gas line?

A copper gas line is a kind of tube system for gas distribution. It’s made from copper. This substance is chosen for its durability, flexibility, and ability to resist corrosion. These properties make it ideal for home gas installations.

What advantages do copper gas lines offer?

Copper gas lines provide superior corrosion resistance and flexibility. They are easier to install than other materials. Their long lifespan and safety features make them optimal for gas distribution systems.

What are the differences between copper gas lines and steel or black iron pipes?

Copper gas lines outperform steel and black iron pipes in several ways. They are more resistant to corrosion and are of reduced weight and easier to handle. Because of these advantages, they are less prone to leakage, making them a preferred choice for many experts.

What steps should be taken prior to installing a copper gas line?

Before installing, you must get local permits and grasp gas flow dynamics. Thorough planning ensures a safe and code-compliant installation.

Which tools and supplies are needed for copper gas line installation?

You’ll need copper pipes, couplings and fixtures, and plumber’s tape. Pipe wrenches, safety gear, and gas-grade sealants are also vital. These materials ensure firm attachments.

How should copper gas lines be routed and positioned for optimal performance?

Ensure that they avoid structural elements and dissimilar metals. Adequate support systems are critical to avoid galvanic corrosion.

What is the correct method to connect and seal copper gas pipes?

Securely connect and seal pipes using gas-grade plumber’s tape and sealants. Always verify your work to avoid leakage.

What methods can be used to detect leaks post-installation of copper gas lines?

Conduct leak tests with a soapy water solution, checking for bubbles. Pressure testing helps ensure the system’s integrity.

What are the key safety regulations for copper gas line installation?

Follow local building codes, verify proper installation depth, and secure the necessary permits. Certified evaluations are also mandatory.

What corrosion problems are typically found in copper gas lines?

Corrosion can occur from contact with different metals or environmental factors. Avoid this by using correct installation methods and conducting routine upkeep.

How can I maintain my copper gas line?

Keep your copper gas line well-maintained with regular inspections, cleaning, and upkeep. This prevents corrosion and leaks, promoting a long lifespan.

When should I choose copper gas lines over steel?

Opt for copper for home applications due to its malleability and low corrosion risk. Steel is more appropriate for high-pressure, industrial settings.